At SMP® Engineered Solutions, we specialize in a range of control products for on- and off-highway vehicles. From applications in lightweight and commercial vehicles to construction and agriculture equipment, we engineer, manufacture, and test custom parts to ensure high performance and lasting durability. Among our extensive product offerings, we provide rotary position sensors of various types to deliver enhanced performance and lifespan for numerous machines and systems. Learn more about these sensors, the different types available, and their applications.

Rotary Position Sensors Explained

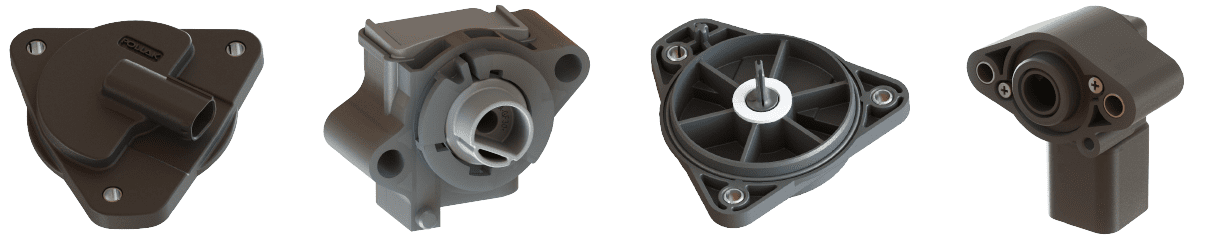

Rotary position sensors give off a ratio metric electrical signal to indicate the rotation angle of an object as it moves either clockwise or counterclockwise around a mechanical shaft. The purpose of these programmable devices is to accurately monitor and position components within machinery, automobiles, ventilation or process control systems, and much more based on rotary movement and angular displacement measurements. They’re ideal for use with components that necessitate frequent positioning modifications.

Rotary position sensors achieve their measurements in varying ways based on the type you choose. These sensors can utilize non-contact or contact technology, which has an impact on their lifespan per the amount of mechanical wear they experience.

Different Types of Rotary Position Sensors

These sensors are available in multiple varieties, each with its own distinct method of measuring a rotating item’s angular displacement. The different types of rotary position sensors include the following:

- Potentiometers. The most prevalent rotary position sensor type, contacting potentiometers utilize a resistive element attached to a moving object to measure angular displacement. As the object’s position changes, so does the element’s resistance, allowing the potentiometer to determine the object’s displacement around a shaft.

- Resolver sensors. These rotary position sensors rely on two perpendicular coils to measure displacement. The coils produce sine waves and cosine waves as an object turns, allowing the sensor to identify the object’s angular position around a shaft.

- Optical encoders. These high-precision rotary position sensors use a rotating disc with opaque and transparent segments. As the disc rotates and light passes through its sections at varying intensities, optical encoders measure angular displacement in correlation to the light beams.

- Hall-effect sensors. Hall-effect rotary position sensors define an object’s angular location by measuring differences in the voltage of magnetic fields. These non-contact sensors monitor shifts in the magnetic field and resulting output voltage changes to determine angular displacement in the Hall element, a magnet, and a turning axis. In this way, the sensors identify the angular position of equipment or systems.

Applications of Rotary Position Sensors

Various automotive industry applications rely on rotary position sensors. For on-highway vehicles, these sensors offer position monitoring in accelerator pedals, engine cooling fans, throttle valves, and related components. They can also monitor rotary motion in heavy-duty, rugged agricultural and construction machinery in off-highway applications. They offer precise measurements for steering columns, engine throttles, hydraulic control valves, and more. In both on- and off-highway vehicles, not only do the sensors enhance efficiency and equipment performance, but they also improve safety, enable precise positioning, and help guarantee accuracy in a vehicle’s operation.

Choose SMP Engineered Solutions for Rotary Position Sensors

High-functioning rotary position sensors are important for accurately measuring angular movement. At SMP, we’ve been developing customizable, high-quality thermal management and vehicle control solutions since 1919. In that time, we’ve built a worldwide network of resources to deliver solutions for vehicles and equipment in a range of industries. We operate from strategic locations both domestically and globally, all holding the most recent ISO 14001, ISO 9001, and IATF 16949 certifications to deliver quality, sustainable solutions in everything from raw material procurement to end-of-line inspections.

SMP offers a wide range of brands and products, including sensors, switches, clamps, ignition coils, electrification and fuel delivery devices, and much more. Contact us today to speak with a specialist about the right rotary position sensor or related vehicle control component for your application.