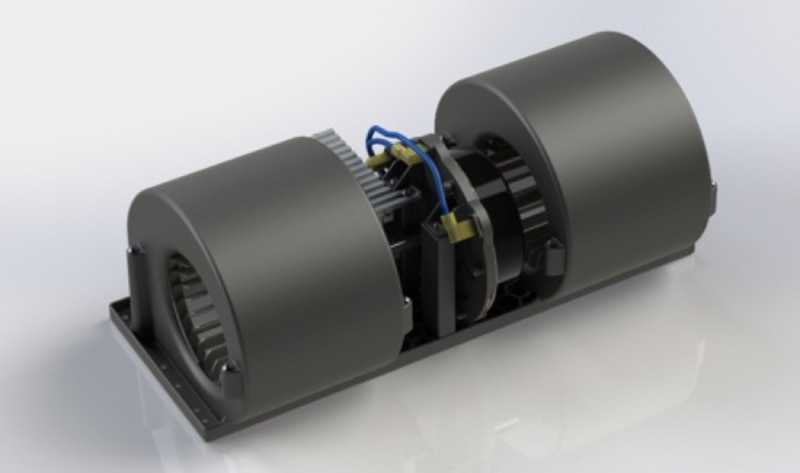

Brushless Motor Technology

- 12 volt and 24 volt

- Very long life- Dual ball bearing, no brushes

- High efficiency at all speeds

- Customized Speed vs Input Signal via software

- Analog or digital control signal

- Can bus or Lin Capable

- Different performance options available up to 400W

- Rugged design, high power density motor

- Low acoustic noise, cogging torque and Low EMI

- Soft stall and locked rotor protection

- Reverse and overvoltage protection

- Over temperature protection and 2 stage fold-back protection

- Customizable Vehicle feedback signal